Recycling CO2 for EOR alongside CCS will not only make a positive contribution to reducing emissions; it can radically overhaul the future of the oil and gas sector as it deals with its decline and transition to lower carbon technologies. Extending the recovery and lifetime of depleting fields, with minimal impact on the environment and climate will:

- Reduce the need for new exploration

- Allow existing pipelines and installations to be reused

- Enable financing and the creation of infrastructure of permanent CO2 injection facilities

- Depending on the nature of reservoir and oil in a given field, the economics can be substantial

- Avoid developing new oil and gas plays in the most controversial areas.

Exploiting hydrocarbons heritage for climate gain

EOR is the process by which CO2 is injected as a gas into the subsurface of active oil reservoirs. When it reaches below 800m it transforms into a liquid where it can be used to displace remaining resources and boost ultimate oil recovery. As the most prominent use of carbon today, EOR is the driver for a host of CCUS (Carbon Capture, Utilization and Storage) deployment strategies.

Pioneered in Texas in the early 1970s, both the USA and Canada have been actively and successfully utilising the technique ever since, without government subsidies.

The production stages of a conventional crude project are often split into three stages: primary, secondary and tertiary. It is at the tertiary, or tail-end stage when typically only around 30-50% of the oil in the reservoir has been recovered with the rest remaining in the ground. This is when facilities are dismantled, wells are permanently plugged and abandoned, and infrastructure is removed from the seabed. CO2 for EOR can reverse the decline of mature fields and increase the overall percentage recovered through several methods including CO2 injection, steam or use of chemicals like surfactants.

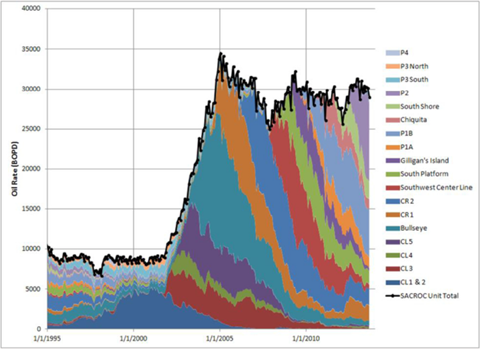

CO2 as a fluid has the ability to mobilize remaining oil towards production wells and has a long history in the USA. For example, carbon injection has been used in The Kelly-Snyder oilfield since 1972. Located on the eastern edge of the Permian Basin in Texas, the operator, Kinder Morgan, has ramped up CO2 injection on the giant oil-producing area which has seen production increase from 9,600 bbl/d to more than 30,000 bbl/d.

The CO2 mixes miscible with oil, improving its mobility, and so allowing it to flow more easily. Most notably, a considerable amount of the injected CO2 is retained in the pore space or dissolved in water. Some CO2 will return to the surface and will be separated and

reinjected.

Hesitancy in Europe

At present, EOR is the only form of largescale, permanent carbon sequestration that is profitable. In order to store huge amounts of CO2 and reach Paris Accord, financing CO2 storage will be very difficult.

The discussions to replicate this technique in the North Sea are proving to be divisive despite its success across the Atlantic and with major developments underway in Africa and Australia. It is the ethics and the logic around “carbon-negative” oil which is contentious and viewed by many as counterproductive.

While it could help reduce emissions from hard-to-decarbonize sectors such as aviation and transport, this very much depends on the source of the CO2 and its eventual consumer.

However, it is important to emphasize that the amount of stored CO2, as a function of EOR, will be greater than carbon emissions created from extra oil extraction. In essence, CO2 can be used to access more oil for short-term use as renewables upscale, while concurrently storing it in the reservoir. Also, EOR may prevent new field developments, a benefit for the environment and climate.

Finally, if gas to power with carbon capture is used, then the measure of kgCO2/bbl produced will be abated.

In a report on advanced extraction methods, the Norwegian Petroleum Directorate (NPD) stated that the remaining oil resources on the Norwegian Continental Shelf that are technically recoverable require advanced EOR methods to be fully exploited. The three-part study showed an average potential of 7% of oil initially in place (STOIIP) in improved recovery and a permanent storage effect for CO2 in the reservoir of 70-100%. Several studies have also been carried out by operators, with support from the Directorate, which show encouraging results and potentially valuable opportunities to store CO2.

An in-house AGR quick calculation of how 7% EOR looks in certain oilfields in NCS is shown in Table below (The required CO2 is estimated to 0.5 ton CO2 per barrel extra oil).

| Field |

STOIIP (million bbl) |

EUR (million bbl) |

RF @ EUR |

CO2 for EOR 7% of STOIIP (million bbl) |

Required CO2/year (million tonne) for a 20 year campaign |

| Ekofisk |

6725 |

3372 |

50 % |

471 |

11,8 |

| Eldfisk |

2832 |

872 |

31 % |

198 |

5,0 |

| Tor |

951 |

199 |

21 % |

67 |

1,7 |

| Valhall |

2737 |

974 |

36 % |

192 |

4,8 |

| Hod |

342 |

96 |

29 % |

24 |

0,6 |

| Total |

13390 |

5670 |

|

941 |

24 |

STOIIP – stock tank oil initially in place

EUR – estimated ultimate recovery

RF – recovery factor

Table 1: An in-house estimate of how 7% EOR potential in a range of NCS oilfields

By producing 941 million barrels, we store 24 million tonnes CO2 per year over 20 years – in total 480 million tonnes. Will it be possible to get the necessary CO2 to realize these values (941*80 USD=75 billion USD)?

Despite the fact that the NPD, academia and major oil companies have carried out studies that indicate increased recovery through the use of CO2, no decisions have been made either in Norway or in other European oil-producing countries to invest in the establishment of CO2 storage in combination with EOR. There are several reasons for this:

- Mammoth investment in infrastructure which will be required if support from government subsidies are limited

- Availability of sufficient CO2 – CO2 has not been available in the North Sea basin

- Reluctance around the perception of safety, environmental and economic risk associated with introducing CO2 into existing wells and facilities.

Moreover, this averseness is largely due to EU taxonomy guidelines forcing through a phase-out of fossil energy and not classifying EOR as a climate mitigating action. Companies- and investors will have to prepare for reporting under a number of new and complex sustainability disclosure standards and adapt as they continue to evolve: ESG (Environmental, Social and Governance) has become really important.

The interest and appetite for CCS endeavors, however, is gaining momentum in Europe in particular.

The surge for CCS

Modelling by the European Commission shows that the EU will need to capture, utilize or store between 300 and 640 million tonnes of CO2 every year over the next three decades if climate neutrality goals are to be achieved. However, financing of CCS is a huge challenge.

Norway has been injecting captured CO2 in saline aquifers since the mid-1990s and is currently spearheading the prolific Northern Lights project – Norway’s first license for CO2 storage on the NCS and a major part of the initiative that the Norwegian government calls Longship: the first ever cross-border, open source CO2 transport and storage infrastructure network.

From two emission points in Southern Norway – HeidelbergCement in Brevik and Hafslund Oslo Celsio waste-to-heat plant – a total of 0.8 tonnes of liquid CO2 will be captured annually for transport to Øygarden to its end destination in a subsea sandstone aquifer 2,000m under the North Sea seabed.

Phase one of the project will be completed in mid-2024 with a capacity of up to 1.5 million tonnes of carbon each year. The project received substantial funding of USD 2 billion from the Norwegian Authorities (taxpayers).

Large-scale CCS is a critical part of Denmark’s ambition to reach net zero carbon emissions by 2045. It recently awarded its first license to inject carbon into depleted oil and gas fields in the North Sea.

By 2025, in the Greensand project, WintershallDea and INEOS Energy plan to inject up to 1.5 million tonnes per annum (Mtpa) of CO2 with plans to increase capacity to 8 Mtpa by 2030. By 2027, TotalEnergies’ Bifrost project aims to inject up to 3 Mtpa and reach 5 Mtpa by 2030. Full funding is not yet decided.

In the UK, the North Sea Transition Authority has established a new team dedicated to carbon transportation and storage ahead of announcing awards for the first ever CCS licensing round.

Adopting CO2 for EOR technologies and upscaling CCS infrastructure could help finance energy demand and lower emissions before more expensive green energy claims the largest stake of the energy mix by midcentury.

According to the latest projections by the IEA, to deliver deep emissions reductions and limit global temperature increases to 2°C by 2060, 14% of cumulative emission reductions must be derived from CCS technologies.

Enduring ingenuity and innovation

A positive legacy of oil and gas towards impactful climate change is the use of its ingenuity and experience to convert deep, largely empty offshore reservoirs as safe and secure sanctums for CO2.

AGR is participating in The LinCCS project to deliver support and advice on geoscience, reservoir and drilling engineering, storage monitoring, facilities, and cost engineering to create an ‘atlas’ of the design and re-design possibilities across different scenarios.

It’s a win-win solution for the sector eager to shrink its carbon footprint and seek more efficient and economical prospects. As operators are looking for ways to reduce their own emissions, offshore CCS is emerging as a competitive alternative. The green shift is underway with the industry taking a solid step-by-step approach to adapt operations and adopt innovation.

Putting carbon to work for climate change

In 2023, the European Commission will table a ‘strategic vision’ for CCS and carbon usage technologies, with the aim of clarifying rules and giving certainty to investors. New legal frameworks and funding streams are already bouncing off the back of a compelling sense of urgency.

Finally, it should be mentioned that the long term perspective of safe CO2 storage is very long, AGR simulates 1,000 years forward modelling of CO2 through absorption, dispersion and transition into calcite minerals.

If the Paris climate accord is to be fulfilled, storing huge amounts of CO2. Without CO2 for EOR, the cost will be outside most governments funding abilities and/or political support.

As many oilfields are in the process of being depleted, time is of the essence as the conversion of existing infrastructure to function as EOR and CO2 storage will take several years to upscale. The window is now open to plan and implement increased extraction with CO2 and accelerate storage efforts.