In a challenging international aid effort to revive the oil industry of Sudan, AGR was appointed by International Petroleum Associates Norway (IPAN) to perform an analytical and training role critical to the enterprise.

Our Engineering and Reservoir experts were tasked with carrying out studies to determine the best methodology for Enhanced Oil Recovery (EOR) at the Heglig oilfield in the South West of the country, part of the Central African Rift System.

Equally important to the long term success of the programme was the training aspect of AGR’s brief, which set out to equip Sudanese geoscientists and engineers with the knowledge needed to make the industry sustainable.

This was a strategic initiative aimed at restoring an industry in Sudan that had shrunk from being a substantial exporter of hydrocarbons to being barely able to meet the country’s own energy demands.

The programme was administered by the Norwegian Petroleum Directorate (NPD) on behalf of the Oil for Development (OfD) programme, which provides foreign assistance focusing on petroleum policy, including legal and institutional framework, resource and HSE Management.

The Heglig oilfield was first developed in 1996 by Arakis Energy and today is operated by the Greater Nile Petroleum Operating Company (GNPOC). Production reportedly peaked in 2006. The field is connected to Khartoum and Port Sudan via the Greater Nile Oil Pipeline.

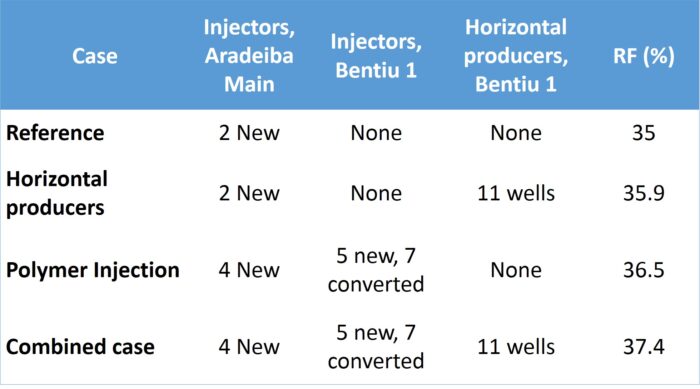

Overview and results from EOR measures

applied to the full field model of Heglig.

Combined case: both horizontal producers

and Polymer injection.

The Challenge

Which enhanced oil recovery strategy was going to be most effective?

African Rift System

Three phases of rifting occurred between the Cretaceous and the Tertiary in this region, resulting in deposition of a thick sequence of sediments over a long time span in the basin. Commercial hydrocarbons had been sourced from the Aradeiba Main, Bentiu 1, Bentiu 2 and Bentiu 3 Formations.

Based on sector model screening, AGR specialists decided that two Enhanced Oil Recovery strategies needed to be incorporated in the full field model. These were horizontal producers in Aradeiba F/Bentiu 1 Formation and polymer injection in Aradeiba Main and Aradeiba F/Bentiu 1.

The reference case used was based on a full field model with existing drilling and production plans for the oilfield, without any EOR actions. An analysis of the results delivered when introducing these EOR strategies into the model showed:

Horizontal Producer Wells

New infill wells within the Aradeiba F/Bentiu 1 reservoirs required a specific length to obtain an adequate initial productivity and sufficient reservoir contact. Simulations including an inflow control device completion gave a small increase to the overall recovery.

Horizontal wells also reduce the water coming from the underlying aquifer. But the main risks with horizontal drilling were found to be expense – more directional well placement would be required compared to vertical wells and more thorough planning.

Polymer Injection

This method was expected to enhance oil recovery by improving the unfavourable mobility ratio for water displacement. The EOR potential is dependent on the polymer viscosity. 12cp based on lab data was considered a highly optimistic case, while 1cp was viewed as the most realistic case due to polymer breakdown and degradation.

Polymers are sensitive to high temperature and high salt concentration. The temperature and connate (fluid trapped in the pores of sedimentary rocks during deposition) water, which proved to be fresh, posed no problems for the Heglig oilfield’s shallowest reservoirs.

Surfactants were also considered as a combination, with polymer injection. The aim of surfactants is to reduce the residual oil saturation in water swept zones, thus the premise for surfactant injection is high residual oil saturation. The residual oil saturation in the water swept zones of Heglig is unknown, and so a program for in-situ measurement was recommended.

Risks with chemical injection include back production in the aspects of facilities, water handling, and polymer degradation during injection that may decrease the desired viscosity.

A combination of Horizontal Wells and Polymer Injection

All cases were constrained by a stepwise decline in total field liquid rate, which was similar in all simulation cases and based on the reference case. In the strategy for Heglig, developed in 2014, two new water injectors in Aradeiba Main were planned for pressure maintenance.

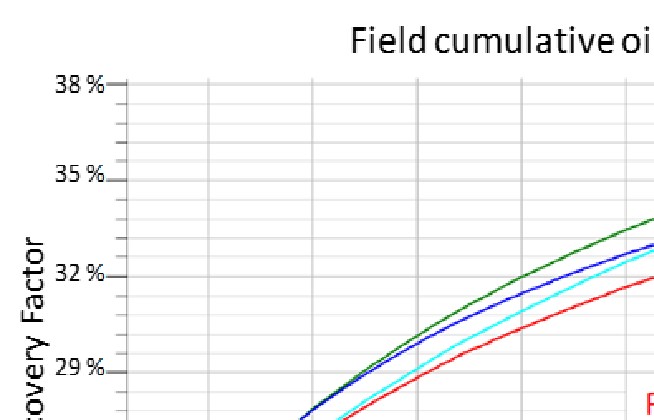

It was found that the applied EOR actions generated extra oil compared to the reference case. Evidently, horizontal wells increased the cumulative production instantly after application, whilst it was some time until the effect of the polymer injection was seen in the recovered volumes.

The AGR Solution

The high stakes demanded rigorous and expert investigation of alternatives

The Heglig oilfield EOR study was challenging on many levels, particularly due to the lack of a complete data set and field history.

Multidisciplinary interaction and the full integration of information proved critical to this project, and to the thorough investigation of the main scenarios of drilling infill horizontal wells, the more advanced chemical EOR by polymer injection and the combination of the two.

Simulation Results – EOR Potential and

Production Curves. Recovery factor in Heglig

1/1 in 2014 was 22%

The recommended work prior to the Front-End Engineering Design (FEED) phase covered a number of areas:

In the G&G disciplines, it was suggested that seismic should be reprocessed to improve frequency content, and shallow events studied and interpreted to see if they could explain features at depth.

In addition, G&G and petrophysical work was recommended in the field static model. This was so a detailed geological analysis of the pilot areas could be made and geosciences input could also be included in history matching.

When it came to reservoir engineering, the recommendations included collection of additional fluid samples to confirm oil viscosity and asphaltene content. This allowed AGR to accurately measure in-situ residual oil saturation and update the simulation models with data from ongoing core experiments on chemical flooding.

Our recommendation was that well planning should be a multidisciplinary effort involving a detailed geological evaluation of the selected area, a well design and borehole stability study and risk and contingency planning.

AGR also advised that there should be detailed planning at the pilot stage, such as front-end engineering design, infrastructure and logistics along with impact assessments covering the production facilities and environmental issues.