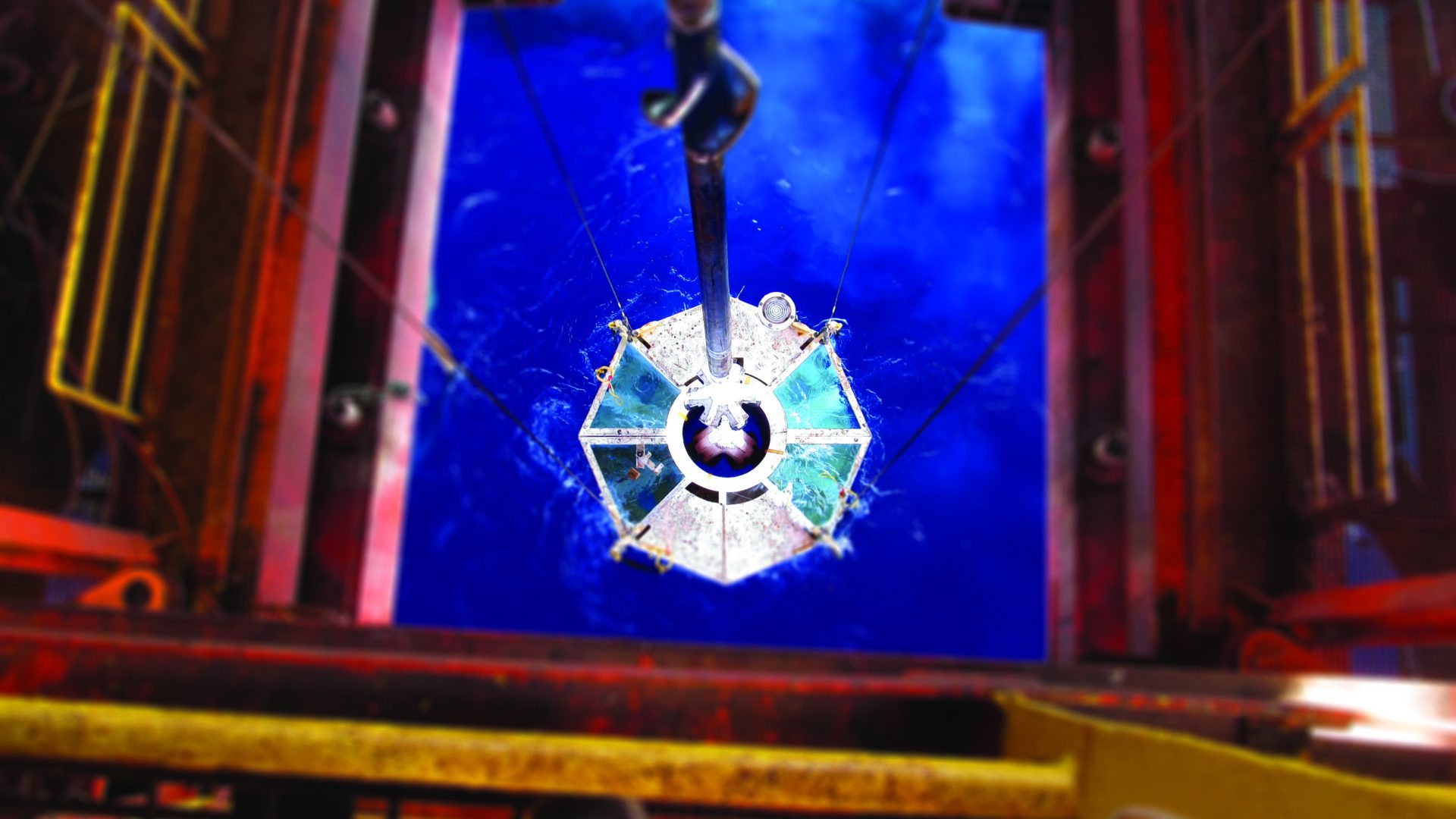

AGR plans and drills a vertical exploration well during multi client campaign in Browse Basin in Western Australia.

AGR’s Australian team on the back of a multi-client campaign, planned, managed and successfully executed drilling, logging and P&A operations of Pryderi-1 Exploration well on behalf of CalEnergy Resources in Yampi Shelf.

The well is located offshore North Western Australia (Browse Basin) and was constructed utilising the semi-submersible Stena Clyde rig following a seven well abandonment project for another AGR client.

The Challenge

- Nearby offset wells had experienced total losses of mud and tight hole sections leading to failure to run wireline logs and difficulty running casing to target depths thus indicating the possibility of similar challenges for drilling Pryderi-1

- Transition of operations from a seven well abandonment campaign to the drilling of a vertical exploration well 135 nautical miles away using the same semi-submersible MODU

- Logistical challenges by utilisation of two remote onshore supply bases: Broome and Darwin – 1,870km apart and 2,230 km and 4,050 km respectively by road from the main O&G hub, Perth

The Complicating factors

- The tidal currents in this region were much stronger than expected based on available information which affected operational performance

- Failure of port crane engine delayed the start of the campaign and resulted in 25.25 hrs of down time while it was assessed and repaired

- A Maritime union strike affected the availability of 3 out of 4 anchor handling vessels for a 24hr period during the campaign

The AGR Approach

AGR assembled a highly experienced team to manage all operational and logistical aspects of the multi-client campaign. The AGR decision to opt for controlled drilling of the riserless top hole sections proved to be critical to successfully maintain hole verticality with the strong tidal currents acting on the drill string.

AGR’s team successfully eliminated tight hole issues experienced by other operators on nearby offset wells. This was achieved by utilising a contingency motor on the BHA to reduce string speed and by applying good hole cleaning operations.

To minimise non-productive time while repairs were carried out on the port crane, all possible pre-spud preparations, including making up the spud BHA and BOP connector change out, were organised, completed and controlled under Management of Change.

AGR’s management of these offline operations was recognised by the Client as crucial in conserving the time & cost KPI’s.

Excellent planning, coordination and communication of the AGR team and 3rd parties also resulted in a 4th supply/support vessel being contracted in advance to help backload equipment and eliminate delays pulling anchors which otherwise would have been unavoidable with the Maritime Union Strike transpiring.

The Result

- The Pryderi-1 well was successfully drilled, logged and abandoned in 16.6 days versus the P50 estimate of 15.7 days. This was an excellent outcome for the Client given the issues related to crane repairs, waiting on weather (tidal currents) and Union induced downtime

- All HSE KPI’s were successfully achieved and all operations were executed in accordance with the Client’s, AGR’s and 3rd Party Contractor standards and international best practices.

The Value Added

- The client was provided with invaluable data in relation to the perceived risks, potential upsides and support for critical decision making by AGR developing a probability based range of cost and time valuations of the project utilising the in-house P1™ estimation tool on iQx software™

- A collective AGR team of experts integrated and executed multiple operations for multiple Clients and seamlessly tackled all planning, logistical and well-construction challenges faced, aiding in minimising the cost for the joint parties involved

- AGR’s Well Delivery Process was used to design and drill the well as per the NOPSEMA accepted Well Operations Management Plan (WOMP)

- The Client was delivered an excellent drilling campaign by fully achieving all KPI’s in HSE and operational efficiency

- Excluding tow times and port crane downtime the well was delivered within 1.6% of AFE

- AGR enabled the Client to drill its first well offshore Australia without the need to have a well engineering team of their own

- AGR’s contract negotations on behalf of the Client as an independent Well Management consultancy proved to save a significant amount in project costs.